Traction batteries are designed for electric forklifts, warehousing equipment, engineering machinery, sightseeing vehicles, and similar applications.

As the power core of electric forklifts, construction machinery, and industrial handling equipment, the service life, range, and safety of a traction battery are 70% dependent on proper daily charging practices. Many equipment failures and premature battery failures are not due to defects in the battery itself, but rather to issues such as overcharging, deep discharging, high-temperature exposure, or dehydration caused by incorrect charging methods.

Pre-charging Inspection

For all types of traction batteries, the pre-charging inspection is the first and most critical step.

Environmental Inspection

The charging area must be well-ventilated, dry, and free from open flames or flammable/explosive materials. It should also be kept away from heat sources and water. Lead-acid batteries release hydrogen gas during charging; adequate ventilation is essential to prevent explosion risks. Lithium batteries should not be charged in high-temperature or confined spaces.

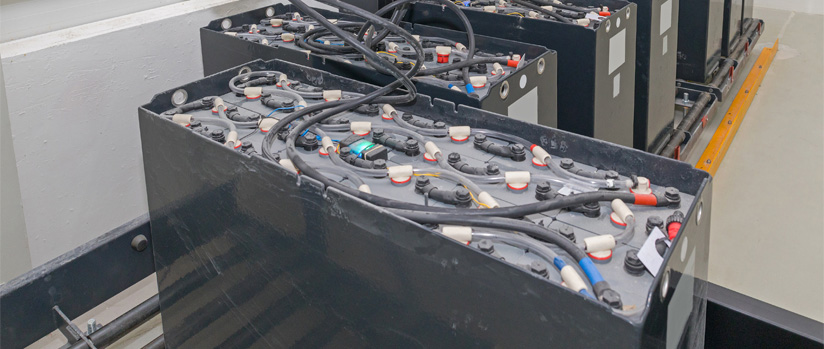

Battery Visual Inspection

Inspect the battery casing for any damage, swelling, or electrolyte leakage. Check the terminal posts for looseness, corrosion, or oxidation. If any abnormalities are found, discontinue use immediately and resolve the issue before charging.

Connection and Equipment Inspection

Confirm that the charger model, voltage, and capacity are compatible with the battery. Never use a charger of mismatched specifications. Inspect the charging cables and plugs for damage, and ensure all connections are secure to prevent overheating or sparking due to poor contact.

State of Charge (SOC) Check

Avoid charging from a deeply depleted state (below 20% SOC for lead-acid, below 10% for lithium-ion). Similarly, avoid frequent top-up charging when the battery is already near full capacity. Develop the habit of "charging as needed" and maintaining "shallow charging and discharging cycles."

The Charging Process

Charging Prohibitions

Never connect batteries of different brands, capacities, or types in series or parallel for charging.

Never perform open-flame work or smoke in the charging area while lead-acid batteries are being charged.

If a battery exhibits severe overheating, unusual odors, or swelling during charging, immediately cut off power and discontinue use.

For batteries in long-term storage, perform a maintenance charge every 1-2 months to maintain the State of Charge (SOC) between 50%-60%, preventing deep discharge and sulfation.

Never charge batteries outdoors in rainy or humid conditions to prevent electrical leakage and short circuits.

Traction Battery Maintenance Tips

Proper charging is the cornerstone of traction battery maintenance. Adhering to standardized procedures can extend battery life by over 30%, ensure stable equipment operation, and minimize downtime losses. Whether for lead-acid or lithium-ion traction batteries, always follow the principles of using matched equipment, standardizing procedures, prioritizing the environment, and performing regular maintenance to ensure a consistent and reliable power output. Following correct charging protocols saves time, money, and trouble. A well-maintained battery is a durable battery.For Your Battery or Forklift Parts Needs, Please Contact Us!