The scientific method for calculating the service life of forklift batteries is not based on time, but rather on the maximum number of discharge cycles the battery can withstand. Currently, mainstream forklift batteries are typically designed for a lifespan of 1,600 cycles. This means that after 1,600 charge-discharge cycles, the battery's charge-holding capacity decays to below 80% of its original factory level, at which point the battery is considered unable to meet operational requirements and must be discarded or replaced.

Scientific and standardized full-cycle maintenance can significantly extend battery service life while reducing equipment downtime and lowering replacement and maintenance costs for enterprises.

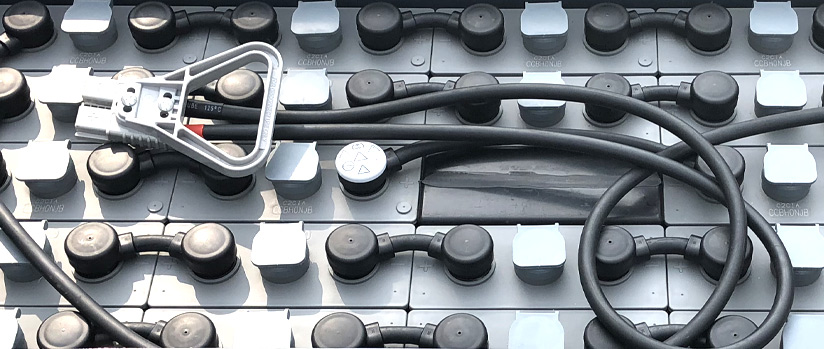

Daily Maintenance Tips for Lead-Acid Batteries

1. Changes in Battery Electrolyte Level During Charging and Discharging:

(1) During battery discharge (i.e., when the forklift is in use): Gases generated within the pores of the battery electrodes during charging are continuously released due to vibration, causing a slight decrease in the electrolyte level.

(2) During battery charging: Under the influence of electric current, water electrolysis occurs within the pores of the battery electrodes, producing a large volume of gas. This causes the electrolyte volume to expand and the liquid level to rise.

2. Regarding Electrolyte Loss:

(1) During battery charging, especially in the mid-to-late stages, water electrolysis occurs due to the charging current, leading to the decomposition of water in the electrolyte. This produces hydrogen (at the negative electrode) and oxygen (at the positive electrode), which are released, resulting in significant water loss from the electrolyte.

(2) During the mid-to-late stages of charging, the electrochemical reactions are intense, and the expelled gases may carry small amounts of electrolyte splashing out of the battery. Although minimal, this can still affect the electrolyte level.

(3) If the electrolyte level is too high during charging, expansion of the electrolyte volume can cause significant overflow, leading to electrolyte loss and corrosion of the battery casing. This severely impacts normal battery operation. To prevent this, the electrolyte level must be strictly controlled.

3. Why Replenish with Pure Water:

(1) The extensive water electrolysis reaction during the mid-to-late stages of charging is the primary cause of water loss in the battery electrolyte.

(2) At all times, regardless of changes in the electrolyte level, the electrodes must remain fully submerged in the electrolyte (they must not be exposed to air). This ensures sufficient reaction between the lead on the electrodes and the sulfuric acid in the electrolyte.

(3) The electrolyte must maintain its specified specific gravity during operation, and consistency in specific gravity across all individual cells must be ensured. Otherwise, uniformity in battery performance cannot be guaranteed. Better consistency allows the battery to perform more effectively.

4. How to Replenish Water:

(1) It is recommended to replenish water during the mid-to-late stages of charging, when the electrolyte volume is at its maximum expansion.

(2)Regularly observe and measure the electrolyte level, ensuring it remains within the specified standard range—neither too low nor too high.

(3) After replenishing water, the electrolyte level must not exceed the specified upper limit. Exceeding this limit can cause electrolyte overflow during charging, leading to sulfuric acid loss, casing corrosion, and environmental contamination.

(4) If the electrolyte level is too low, the electrodes may become exposed to air, causing oxidation. This also increases the electrolyte's specific gravity, accelerating electrode corrosion and significantly reducing battery lifespan.

Lead-acid batteries are industrial consumables highly dependent on maintenance practices. Standardized charge-discharge management, regular inspections at appropriate intervals, and proper storage can extend battery life by 30%–50%.

For any forklift battery needs, technical questions or maintenance issues, please contact us. We offer professional, efficient solutions and full support to keep your equipment running reliably.