Forklift oil leaks are a common problem. When a forklift leaks during use, it's important to promptly investigate the cause and repair it. Typically, oil leaks can be caused by aging or damage to hydraulic system seals, loose or damaged oil line connections, or other factors. Furthermore, oil leaks can also be caused by not filling with the specified lubricant or by using a poor-quality lubricant.

We have parts suitable for mainstream models (Toyota, Linde, Heli). Click https://www.lifttops.com and buy immediately if you need. We will have professional technicians to provide you with guidance. Some sets also include installation tools, so novices can also get started.

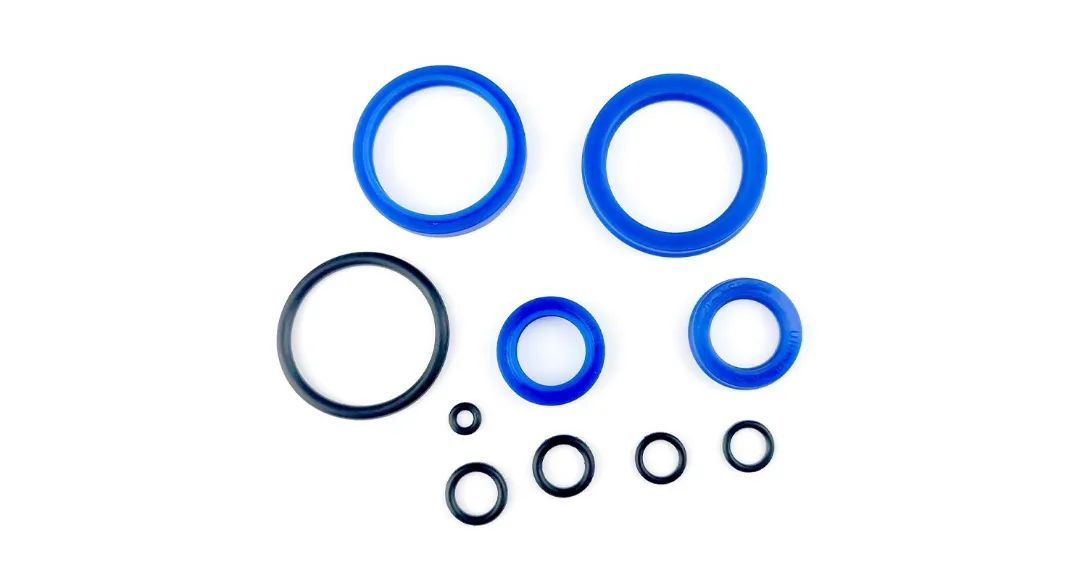

Forklift oil seals can be categorized as hydraulic cylinder seals, Multi-section Control valve seals, and valve seals. Below, we'll share replacement methods for various forklift oil seals.

How to Replace the Oil Seal on a Forklift Hydraulic Cylinder

01 First, remove the brake springs or brake screws at both ends of the forklift hydraulic cylinder. Alternatively, remove the screws on the top of some cylinders by twisting them out.

02 Loosen the guide sleeves on both sides or one guide sleeve, then remove the seals from the guide sleeves and replace them with new wear-resistant ring oil seals.

03 Replace the piston rod inlet oil seal inside the forklift hydraulic cylinder. If the seal is deformed or aged and difficult to remove, soak it in boiling water for 10 minutes to remove it.

How to Replace the Oil Seal on a Forklift Multi-section Control Valve Valve

01 Disassemble the multi-way valve operating handle and remove the retaining ring and retaining pin.

02 Use a Phillips screwdriver to loosen the two screws on the multi-way valve, then open the cover.

03 Remove the oil seal or O-ring inside. Install the new oil seal or O-ring, ensuring it snaps into place. Replace the cover, tighten the screws, and then install the retaining pin and retaining ring, connecting them to the operating handle.

04 Perform a test run. If all other problems are resolved, the forklift can be returned to the operator for use.

Replacing Forklift Valve Seals

If the exhaust smoke emitted by a forklift is blue when it's started and the forklift's oil consumption is accelerated, it can be concluded that the forklift's valve seals are faulty. In this case, we recommend removing the forklift's cylinder head and replacing the other valve seals. The forklift valve seal replacement method is as follows:

Remove the forklift's cylinder head and use a hard object to hold the valves in place before replacing the valve seals.

You can also replace the forklift's valve seals without removing the cylinder head. To replace the intake or exhaust valve seals on a particular cylinder, use a strong string to hold the valves in place. If necessary, remove the spark plug for that cylinder and introduce high-pressure air into the spark plug hole to hold the valves in place. Alternatively, rotate the engine and allow the piston to press against the valves while removing and installing the valve seals. This method avoids problems such as cylinder head gasket damage, timing errors, and coolant contamination or defects during cylinder head removal, and also saves replacement time.

Forklift Oil Seal Replacement Precautions

01 Before replacement, prepare the required number of oil seals.

02 The oil seal must be kept clean from the moment it is unsealed to the moment it is installed.

03 Before installing the oil seal in the forklift, inspect the oil seal thoroughly. Measure the dimensions of each seal component to ensure they match the shaft housing dimensions, or verify the correct oil seal part number.

04 Recheck the oil seal lip for damage or deformation, and the spring for loosening or rust. Prevent the forklift oil seal from being unevenly stored during transportation, which could cause it to be squeezed or impacted, potentially damaging its roundness.

05 For installation tips, gently touch the seal to ensure it is smooth and round.

06 Before installing the oil seal in the forklift, inspect the oil seal thoroughly. Measure the dimensions of each seal component to ensure they match the shaft housing dimensions, or verify the correct oil seal part number.

07 Before installation, apply a moderate amount of hydraulic oil/grease between the lips of the forklift oil seal to lubricate them. This prevents dry grinding of the lips during sudden shaft activation, which could affect the interference fit. After applying the hydraulic oil/grease, assemble the seal as soon as possible.

08 After the oil seal is installed, if the machine will not be installed immediately, it is recommended to cover the seal seat with a cloth to prevent foreign matter from adhering to the seal. Ensure that your hands and tools are clean when applying hydraulic oil/grease to the forklift oil seal.

09 During installation, avoid sharp edges, align the seal, and avoid twisting or skewing. It is recommended to use hydraulic equipment or a sleeve tool for installation. Do not apply excessive pressure, and use a steady, slow speed.

10 When installing on a stepped shaft, use copper guides or plastic tape to protect the transition to prevent damage to the forklift oil seal.

Frequent forklift failures are a common problem for users. When a forklift frequently malfunctions during operation, it's important to carefully consider the possible causes. The most common cause is improper component replacement.

For example, if a forklift user fails to properly connect the power cord or secure the screws when replacing the battery, the battery won't charge or discharge properly, affecting the forklift's efficiency. Similarly, the forklift's electrical and mechanical systems require regular inspection and maintenance to prevent malfunctions.

To avoid these issues, users should choose high-quality forklifts and parts when purchasing them or replacing key components.

During installation and replacement, strictly follow the manufacturer's technical instructions to ensure proper installation and secure connections. Additionally, regular forklift maintenance, including lubricant changes and seal inspection and replacement, is essential to extend the forklift's lifespan and improve efficiency. For technical guidance or forklift parts, please contact us!