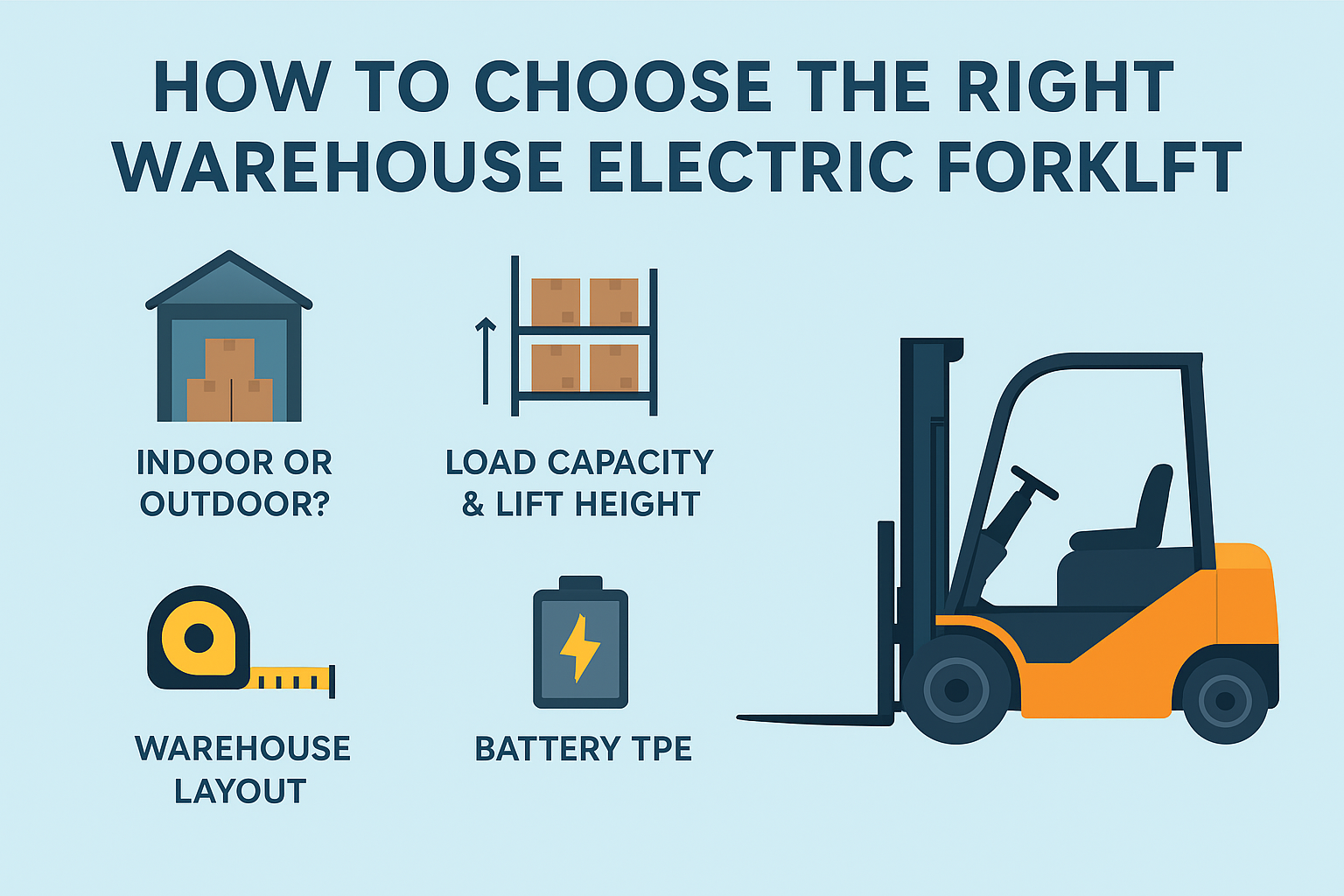

In warehouse logistics management, electric forklifts have become essential tools for improving efficiency and reducing costs. However, with the wide variety of models available on the market, many companies often feel confused when it comes to selection. Choosing the wrong model can not only impact operational efficiency but may also lead to resource waste. Today, we will delve into the five key factors for selecting the right electric forklift for warehouse operations, helping you make an informed decision.

Point 1: Determine Load Capacity and Lift Height

This is the primary consideration for model selection. You need to define:

The maximum weight of your typical loads

Light-Duty (≤ 1.5 tons): We recommend electric pallet trucks or electric stackers, ideal for routine cargo handling.

Medium-Duty (1.5 - 3 tons): An electric counterbalance forklift is a suitable choice, meeting the vast majority of warehouse needs.

Heavy-Duty (≥ 3 tons): Opt for a heavy-duty electric forklift or a custom-designed model to ensure both safety and efficiency.

The maximum height of your warehouse racking

It is advisable to select a forklift with a load capacity 15-20% greater than your maximum load weight to ensure operational safety. Simultaneously, the lift height should be slightly higher than the top shelf level to allow for an adequate safety margin during operation.

Point 2: Determine Fork Length

The fork length must be matched with the dimensions of the pallets you use daily:

Standard Pallets: Typically require forks between 1070-1200mm in length.

Non-Standard/Long Loads: Longer forks are necessary for handling extra-long goods.

General Rule: The fork length should be at least two-thirds of the pallet's length to ensure optimal stability.

Point 3: Choose Between Outriggers or No Outriggers

This is a critical decision in the selection process:

Stackers with Outriggers (e.g., Model TB): Ideal for handling single-face pallets. The outrigger design provides superior stability during lifting.

Stackers without Outriggers (e.g., Models TFA, TKA, TF): Designed for double-face pallets, as the forks can directly insert into the pallet bottom.

Choosing the wrong type will render the equipment unusable for your pallets. It is therefore paramount to base your selection on your specific pallet type.

Point 4: Determine Gradeability Requirements

If your operational environment includes slopes, the forklift's gradeability must be considered:

Most standard electric forklifts offer a gradeability between 5% and 10%.

For environments with significant slopes, selecting a model with superior gradeability is essential.

Point 5: Verify the Dimensions are Suitable

The final step is to ensure the forklift's physical dimensions are compatible with your workspace:

Measure aisle widths, elevator dimensions, and doorway sizes.

Consider the turning radius requirements.

Verify that the forklift's overall height is lower than the lowest beam in your racking system.

Selecting the right electric warehouse forklift requires a comprehensive consideration of all five factors outlined above; each is indispensable. Making the correct choice will not only boost your operational efficiency and reduce running costs but, most importantly, will ensure a safer working environment.

We hope this guide provides you with practical direction for your selection process. If you are sourcing high-quality, cost-effective parts for your electric warehouse forklifts, please do not hesitate to contact usOur team is ready to provide tailored services based on your specific warehouse environment and operational needs.