As the core of a forklift's hydraulic shift system, a malfunctioning solenoid valve can directly impact operational efficiency and equipment safety. Don't panic! This highly detailed troubleshooting guide will help you quickly identify and resolve the four most common solenoid valve issues, giving your forklift a new lease of life! Today, we'll delve into the top four typical forklift shift solenoid valve failures and their troubleshooting methods, helping you become a "solenoid valve doctor" step by step!

If you need to check the specific models of forklift solenoid valve suitable for your equipment, you can click www.lifttops.com.

Fault 1: The solenoid valve has no power

(the wiring connector is loose/falls off)

Symptom: The forklift will not shift, and the solenoid valve is completely unresponsive (no "click" sound).

Core Cause: The simplest fault! The power cord connector is loose, poorly connected, or completely disconnected, preventing the solenoid valve coil from receiving power.

How to diagnose this problem? Visually inspect the solenoid valve terminals. Shake the wiring harness to see if there is any looseness.

Troubleshooting:

Tighten: Locate the loose terminal and tighten it securely with an appropriate tool (such as a screwdriver or wrench). Inspect the wires for corrosion or breakage, and replace the terminal or harness section if necessary.

Preventative Tip: Regularly check the wiring harness and connectors to avoid strain and wear.

Fault 2: Solenoid valve coil burned out

Symptoms: The solenoid valve does not release oil after power is applied (the oil circuit is blocked). Observe the coil for deformation, discoloration, or signs of burning. Using a multimeter, the resistance across the coil is infinite (open circuit). The internal core (iron core) has no electromagnetic attraction.

Core Cause:

Insulation damage due to moisture: Rainwater and flushing water seep in, causing the coil to short-circuit and burn. (This is a key precaution!)

Excessively stiff springs and excessive reaction force: Coil design/manufacturing issues (few turns, insufficient suction) lead to prolonged overload, overheating, and burning.

How to diagnose this problem? The resistance range on a multimeter is crucial! Remove the wiring and measure the coil resistance. Normally, the resistance should be between tens and hundreds of ohms. If the display reads "OL" or infinite, the coil is burned.

Troubleshooting: Replace the coil or the entire solenoid valve.

Prevention Tips:

Be extremely waterproof! Avoid high-pressure water jets directly into the solenoid valve area. Check for proper sealing. Choose genuine spare parts: Make sure the parameters (voltage, power, thrust) of the replaced coil or solenoid valve match those of the original manufacturer.

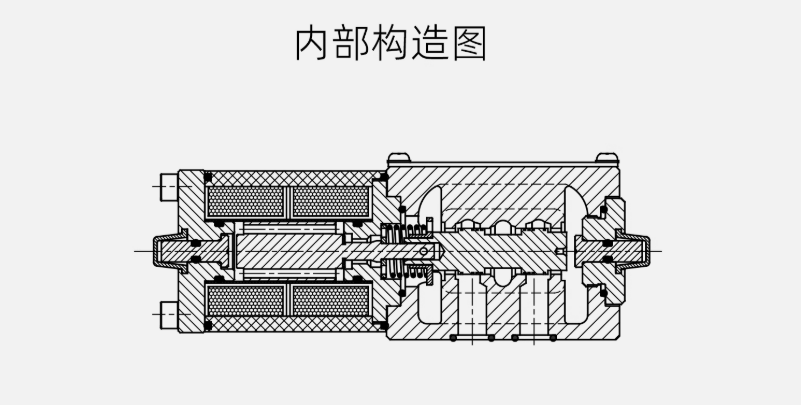

Fault 3: Solenoid Valve Spool Stuck

Fault Symptom: The solenoid valve makes a sound when powered on, but the spool fails to move properly, resulting in poor or complete oil flow. This may be accompanied by shifting difficulties and sluggish response.

Core Cause: Mechanical impurities (metal shavings, seal debris, dirt) in the hydraulic oil are lodged in the gaps. Insufficient lubricant or incorrect type.

How to diagnose? Sounds may be heard when powered on (possibly normal), but the function is abnormal. This requires consideration of other fault symptoms.

Troubleshooting Methods:

Remove the solenoid valve (record the disassembly sequence and wiring locations!).

Remove the spool and valve sleeve assembly.

Thoroughly clean the spool and valve sleeve bore using a high-purity solvent (such as CCl4 carbon tetrachloride - ensure safety precautions and good ventilation) or a dedicated cleaning agent.

Check that the spool slides freely within the valve sleeve without any binding.

Inspect and clean the lubricator to ensure the oil spray holes are clear and use the appropriate amount of lubricant.

Carefully reassemble the valve, ensuring the wiring is correct.

Prevention Tips:

Keep the hydraulic fluid clean! Replace the filter regularly and change the oil according to the maintenance interval.

Lubricator Maintenance: Regularly check the oil level in the oil cup, clean the spray holes, and use the specified lubricant.

Fault 4: Solenoid Valve Oil Leakage

Fault Symptoms:

External Leakage: Visible oil seepage from the exterior of the valve body (such as seals, screws, and pipe joints).

Internal Leakage: More subtle! The solenoid valve should close after power is removed, but it doesn't actually close tightly. Symptoms include: After the shift command is canceled, pressure or flow remains in the relevant oil circuit (for example, the oil gun continues to discharge oil after the preset oil level is reached), or the system has difficulty maintaining pressure.

Causes: Valve Component Damage: Worn or scratched valve core/seat.

Foreign Object: Impurities become lodged between the valve core and seat, preventing full closure.

Diaphragm Rupture: For diaphragm valves, diaphragm damage leads to seal failure.

Seal Failure: Wear and aging of internal seals (such as the sealing ring on the sliding valve) can cause oil (or gas) leakage between chambers.

External Leakage: Loose mounting screws; aging or damage of O-rings or sealing gaskets; or cracks in the valve body or end cap.

Troubleshooting:

Replacing the diaphragm: If the diaphragm is confirmed to be damaged, replace it immediately.

Cleaning the valve: Disassemble and clean the valve core and seat to remove any foreign matter that could cause a loose seal.

Replacing worn parts: If the valve core, seat, or internal seal is worn, replace the corresponding component or the entire valve.

Treating oil blowby: Inspect and replace damaged spool seals or gaskets.

External leakage: Tighten any loose screws. If tightening is ineffective, replace the sealing components (O-rings, gaskets) at the leaking site, or replace any cracked valve body/end cap.

Loose wiring, burnt coils, stuck valve cores, and internal and external leakage—these four common causes of forklift gear solenoid valve failure. Understanding their symptoms, causes, and troubleshooting methods will allow you to respond quickly to most faults and minimize downtime. Remember: Safety first! Always disconnect the power supply and release system pressure before operating!

If you need forklift parts, please contact us.