A manual pallet jack is a dual-purpose vehicle for high lifting, loading/unloading, and short-distance transportation. It features smooth lifting, flexible steering, and easy operation, making it an essential auxiliary tool in material handling. Most enterprises use them, but improper operation can also lead to serious accidents. Below are the safety operation precautions for manual hydraulic pallet jacks.

Pre-Use Safety Management

Before operating a manual pallet jack, the operator must be properly trained.

(1) Before use, inspect the hydraulic cylinder for any leaks.

(2) Before use, check if the wheel/sprocket assembly is functioning properly.

(3) Before use, inspect the wheel/sprocket assembly for any entangled debris and remove it.

(4) The control handle must be intact, with the switch making good contact, free from sticking or poor connection issues.

Safety Management During Equipment Operation

Loading

1)Only pallets must be used for loading goods. It is strictly forbidden to use the bottom of the goods as a substitute for a pallet, as this may cause uneven force distribution, leading to damage or collapse of the goods. The forks must be fully inserted under the pallet to lift the load, ensuring its stability.

2)During loading, the center of gravity of the goods must be placed at the load center of the forks. Off-center or unbalanced loading is strictly prohibited.

3)Do not impact the forks with goods during operation.

4)It is strictly forbidden to operate with loads exceeding the pallet jack's rated capacity.

5)The loaded height must not exceed 1.5 meters, and the goods must not overhang the pallet by more than 5 centimeters.

6)After loading, a safety confirmation of the load must be performed before proceeding with further operations. Otherwise, reloading is required.

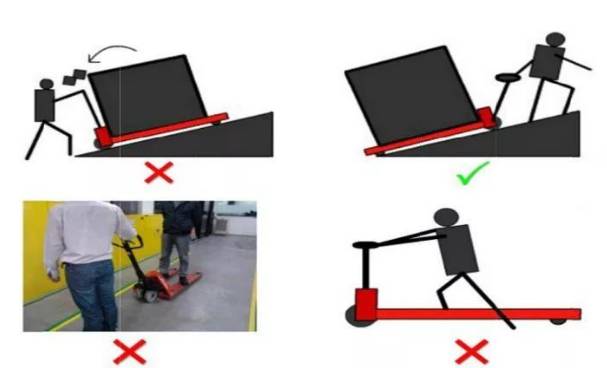

Moving/Transporting

The pallet jack must be operated by only one person.

1)Operation must be carried out on hard, flat surfaces. Avoid holes and uneven ground.

2)Excessive speed is strictly prohibited (do not exceed 3 km/h, noting that normal adult walking speed is 5 km/h). Reduce speed when turning to prevent the pallet jack from grounding or tipping over.

3)During use, always pay attention to the pathway and surroundings to avoid collisions with other people, merchandise, racks, or other objects.

4)When transporting a load, lower the forks for safety during travel.

5)When unloaded, the pallet jack must not be used to carry people or be allowed to slide freely down slopes.

3. Post-Use Equipment Safety Management

1) When not in use, the pallet jack must be lowered to its lowest position and stored in the designated area.

2) Damaged pallet jacks must be repaired or scrapped; their use is strictly prohibited.

3) Charging (if applicable) must only be conducted at dedicated charging stations. Charging is prohibited in living areas, near flammable materials, inside enclosed warehouses, or similar locations.

Prohibited Practices During Pallet Jack Operation

● Overloading, off-center loading, or operating with a single fork is strictly prohibited.

● Impacting or quickly snatching loads with the forks is strictly prohibited.

● Using braking inertia to slide or release items is strictly prohibited.

● Allowing personnel to stand on the pallet jack to steady loads or act as counterweights is strictly prohibited.

● Using the forks to lift personnel for working at height is strictly prohibited.

● Carrying or towing people on the pallet jack is strictly prohibited.

● Parking or obstructing emergency exits, access to firefighting equipment, or areas near flammable materials is strictly prohibited.

● Traveling across slopes exceeding 7° with unsecured loads or relying on human effort to stabilize them is strictly prohibited.

Maintenance and Inspection

1. Frame and Fasteners: Tighten any loose wheel axles and nuts. Check for damaged welds or support plates. For stem-type casters, ensure nuts are tight or stems are securely riveted, and verify that mounting brackets are not bent. When installing casters, always use lock nuts or anti-loosening washers.

2. Lubrication:Apply lubricant regularly. Grease should be applied to the wheel axles, inside seals, and the friction points of roller bearings to reduce friction and ensure smooth rotation.

3. Casters:Visually inspect casters for wear. Ensure they rotate freely without obstruction from debris, and that they are neither too loose nor too tight. Replace damaged casters to prevent unstable operation. After inspection or replacement, always secure the axle using lock washers and tightened nuts (as a loose axle can cause the wheel hub to rub against the bracket and seize).

Safety is in your hands—literally, when you operate a pallet jack. From the initial inspection to the final parking spot, every step matters. Don’t cut corners. Share this guide with your team, reinforce these practices daily, and commit to zero incidents. Your awareness is the best safety feature. Operate with care, every time. For all your forklift parts requirements, please contact us!