According to data from the Forklift Branch of the China Construction Machinery Association, the total market size for counterbalanced electric forklifts in China reached approximately RMB 150 billion in 2023 and is projected to exceed RMB 180 billion by 2025. The expanding market share of electric forklifts continues to encroach upon that of internal combustion engine forklifts.

As a significant form of electric forklift, the diesel-to-electric counterbalanced forklift conversion demonstrates clear market advantages and evident economic benefits.

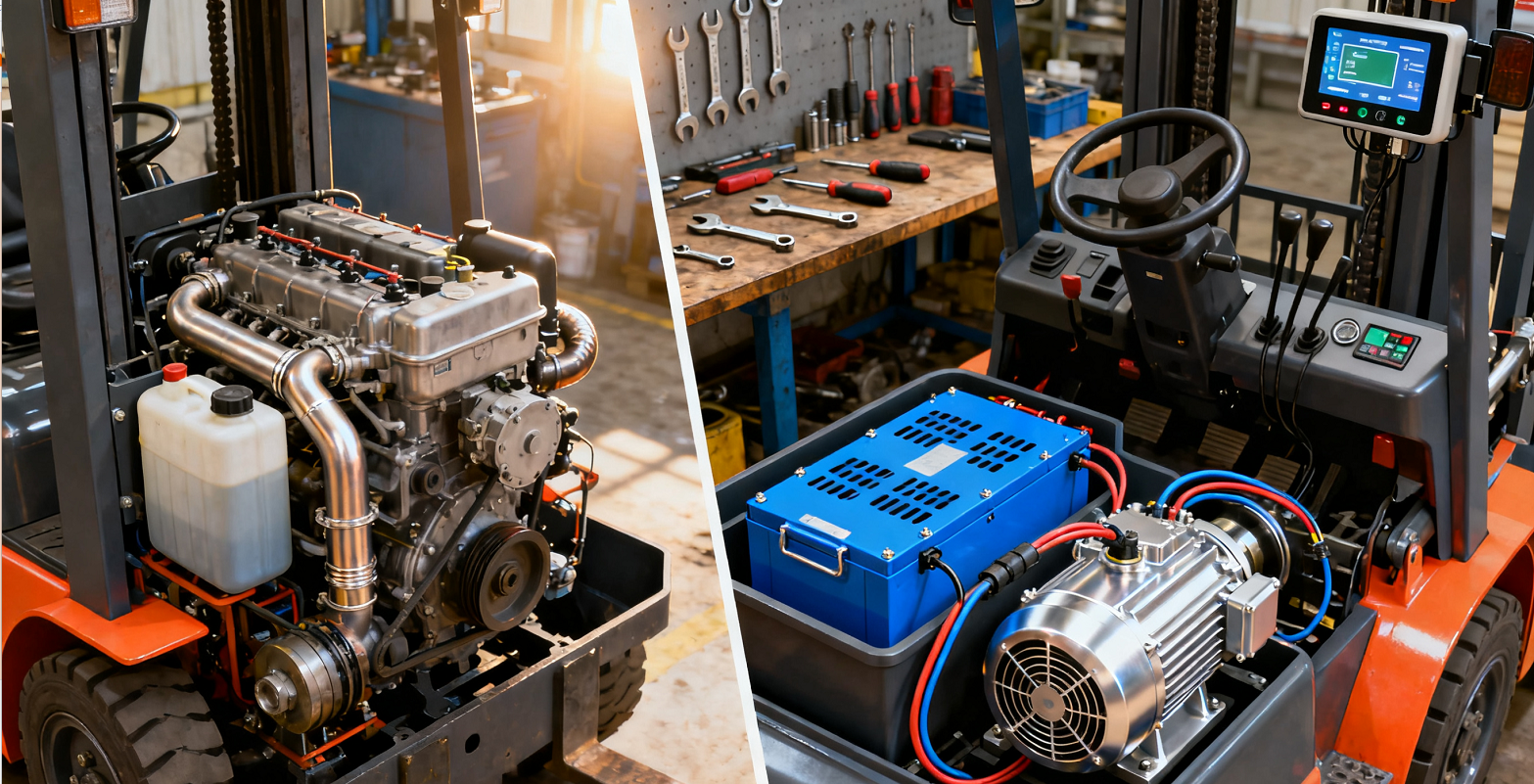

What is "Diesel-to-Electric Forklift Conversion"?

In simple terms, "diesel-to-electric conversion" refers to the professional technical process of removing the powertrain components—including the engine, transmission, and fuel tank—from an existing internal combustion forklift and replacing them with an electric drive system centered around a motor, electronic controls, and a battery pack. This is essentially equipping your conventional forklift with a new, "green," electric heart.

Environmental Performance

Electric forklifts produce no exhaust emissions, reducing environmental pollution and improving air quality.

Indoor Adaptability

Ideal for operation in enclosed spaces such as indoor facilities.

Asset Utilization

Revitalizes existing equipment assets, avoiding the high investment required for complete replacement. Diesel-to-electric converted forklifts offer a clear price advantage, costing over one-third less than new electric forklifts, demonstrating significant cost-effectiveness.

Technical Solution Analysis

Selecting an appropriate diesel-to-electric conversion solution is critical to project success and requires comprehensive evaluation of multiple technical factors.

Control System Selection

Controller Type: Select a controller compatible with the motor to ensure precision control and responsive performance

System Integration: Evaluate the controller's integration capability with other vehicle systems

Protection Features: Verify the control system incorporates comprehensive safety protections

Charging System Options

Conventional Charging: Suitable for single-shift operations (8-10 hours charging time)

Fast Charging: Ideal for multi-shift operations (2-4 hours charging time)

Opportunity Charging: Enables short-duration charging during work breaks

Battery Swapping: Utilizes spare batteries for rapid "refueling" operation

Hydraulic System Modifications

Compatibility between hydraulic pump and electric motor

Potential for system efficiency optimization

Assessment of seal and pipeline aging condition

Consideration of electro-hydraulic power assist implementation

The optimal technical configuration should be determined through holistic consideration of operational intensity, budget constraints, maintenance capabilities, and long-term ownership costs. For high-intensity operating environments, the recommended solution combines AC motor + lithium battery + smart controller configuration.

Key Considerations for Diesel-to-Electric Conversion

The diesel-to-electric conversion solution generally offers favorable economics for forklifts with high utilization rates, stable operating conditions, and well-maintained original equipment. For older or severely worn forklifts operating under harsh conditions, direct replacement with a new electric forklift is typically recommended.

Assessment of Original Equipment Condition

Evaluate the overall condition of the existing diesel forklift, including wear levels of major components such as the chassis, mast, and hydraulic system. Well-maintained forklifts represent more suitable candidates for conversion.

Analysis of Application Scenarios

Clarify the primary operating environment: indoor versus outdoor use, single-shift versus multi-shift operations, and frequency of charging requirements. These factors directly influence battery type and capacity selection.

Battery Technology Selection

Select appropriate battery technology based on operational needs: lead-acid batteries offer lower initial cost but slower charging, while lithium batteries provide faster charging and longer service life at a higher purchase price. Balance initial investment against long-term operating costs.

Converter Qualification Selection

Choose conversion service providers with proper certifications and demonstrated experience. Verify quality assurance and after-sales support through review of project portfolios and customer references.

Charging Infrastructure Preparation

Assess whether existing charging facilities meet requirements or if new equipment installation is necessary. Consider charging time, quantity of charging stations, and facility layout.

Operator Training Program

Implement comprehensive training for electric forklift operation, ensuring operators understand unique characteristics, charging protocols, and routine maintenance requirements.

Maintenance Planning

Develop scheduled maintenance programs covering battery care, motor inspections, and control system checks to ensure long-term reliable operation.

Return on Investment Analysis

Calculate payback period by considering conversion costs, operational savings, and reduced maintenance expenditures to confirm project economic viability.

Diesel-to-electric conversion represents not merely a technical upgrade, but a forward-looking strategic investment. It achieves an optimal balance among economics, environmental responsibility, and practical utility, offering enterprises a low-risk, high-return pathway toward sustainable transformation.

If you wish to determine your forklift's suitability for conversion or require any type of forklift parts, please contact us !our specialized team remains available to provide complimentary consultation and evaluation services.