Forklift contactors are contact devices used in forklifts, typically mounted on the fork arms of a forklift. They are used to contact and lift goods in order to move them from one location to another. Forklift contactors typically consist of a pair of fork arms that can be adjusted in width to accommodate different types and sizes of goods. They can be hydraulically or mechanically controlled, allowing the fork arms to move up and down and open and close. This allows forklifts to easily grasp, carry, and stack goods. Forklift contactors are widely used in logistics, warehousing, and manufacturing industries, improving work efficiency and safety.

Function of a Forklift Contactor

A contactor is an electrical device in industrial electrical systems that uses a coil of current to generate a magnetic field, closing contacts to control a load. It is used to frequently connect and disconnect DC main circuits.

Simply put, it is a device that uses a low-current coil to control the on/off of a high-current circuit. Its primary function is to control a high-current load with a low current. This allows for remote control and self-locking to prevent accidents caused by false operation.Because of the low-current control, the protection circuit is simple and reliable.

What is a DC contactor?

Contactors are widely used to control motors and other loads. They can frequently connect and disconnect the main circuit of electrical equipment remotely. They work in conjunction with protective devices such as thermal relays and fuses to provide protection against overloads, phase failures, short circuits, and voltage drops.

Contactors are generally categorized as AC contactors and DC contactors. We currently primarily sell DC contactors. You can click on the link to view our products:https://www.lifttops.com/

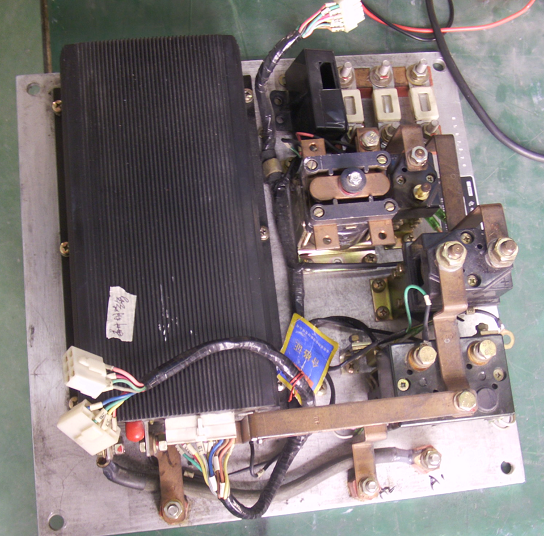

Contactor components

Magnetic system (iron core, static iron core, electromagnetic coil);

Contact system (silver alloy);

Arc extinguishing device (when the contactor is operating, current flows through it, sparks are generated, and the arc is extinguished by magnetic blowout).

Differences Between Imported and Domestic Contactors

1. Appearance Color Difference

The coil packaging and plastic bracket of imported contactors are gray, while those of domestic contactors are glossy black.

The iron bracket of imported contactors is golden yellow, while that of domestic contactors is white.

2. Copper Bar Difference

The copper bar of imported contactors has the GE logo, while domestic contactors do not.

3. Coil Resistance Difference

Imported GE contactors have lower resistance than domestic contactors, and the resistance parameters of products of the same model are relatively stable and very close. Domestic contactors have relatively unstable resistance values of the same model, with large variations.

Common contactor problems and precautions:

If a contactor fails to close, common causes include: a low power supply, a defective contactor, or a problem with the control circuit.

Solution:

01 Determine the General Scope of the Fault

First, use a multimeter to check whether the control circuit power supply voltage is normal. Generally, if the actual voltage is less than 85% of the rated voltage, the contactor will not engage properly. If the control circuit voltage is normal, the likely cause is a wiring problem or a contactor problem.

Next, check whether the contactor coil voltage is normal. Again, the actual voltage must not be less than 85% of the rated voltage. If the voltage across the coil is normal, the contactor is faulty. If there is no voltage across the coil, the control circuit is faulty.

02 Locate the Fault Point

A:If the power supply is dead, check whether the upstream power supply is receiving power; check for blown fuses.

B: If the problem is with the contactor, replace the contactor. Also, check the coil for signs of burning or any unusual odor to determine if the coil is burnt. You can also determine if the contactor coil is burnt by measuring resistance with the power off (normally, there should be a certain resistance; if it is burnt, the resistance should be infinite). Check the contactor armature for sticking or rust, etc.

C: If the problem is with the wiring. First, you must be able to understand the control circuit diagram and the relationships and principles between the various components. Secondly, you must understand the potential consequences of problems in each link of the circuit, based on principle analysis.

For example:

The contactor opens when the button is released; this indicates a problem with the contactor's self-locking circuit.

The contactor clicks when the button is pressed; this could indicate a stuck contactor or a normally closed contact locked to its own coil.

The contactor has no response when the button is pressed. After eliminating power and coil issues, this could indicate a problem with the normally closed contact of the button/thermal relay, a problem with the normally open contact, or a break somewhere in the wiring.

Usage Precautions

The contact surfaces should be regularly maintained and cleaned. Oiling is prohibited. Metal beads formed on the contact surfaces due to arcing should be removed promptly. Severe contact wear should be promptly replaced. However, please note that the black oxide film formed on silver and silver-based alloy contacts during arc interruption has very low contact resistance and will not cause contact failure. Therefore, filing is not necessary, as this will significantly shorten the contact life.

Forklift contactors are widely used in logistics, warehousing, and manufacturing, improving the efficiency and safety of cargo handling. When selecting a forklift contactor, factors such as cargo size, weight, and operating environment should be considered to ensure safe and efficient handling. If you need forklift parts or have technical problems, please contact us!