Hello everyone! Today, we're going to talk about a crucial component in the field of logistics, warehousing, and cargo handling—the forklift brake. The forklift brake doesn't just come into play when parking; its performance is directly tied to your operational safety. Imagine the trouble if a forklift suddenly lost its braking ability in the middle of a busy workday! But don't worry—this article will demystify forklift brakes for you, covering their uses, key features, purchasing considerations, and maintenance tips to help you make the most of this essential equipment. Ready? Let’s dive into the world of forklift brakes together!Click lifttops.com to learn more about forklift parts.

Functions of Forklift Brakes

The primary role of forklift brakes is to ensure stable and reliable stopping when deceleration or parking is required. Their working principle is straightforward: they convert the kinetic energy of the forklift into heat through friction, thereby reducing speed or bringing the vehicle to a complete stop. Much like the brakes in a car, forklift brakes enable precise speed control during cargo handling, allowing operators to respond promptly to unexpected situations and prevent accidents.

Moreover, the functionality of forklift brakes is not limited to flat surfaces. In electric forklifts, the braking system incorporates advanced electronic control technologies, such as regenerative braking. This system captures and stores energy generated during braking, enhancing energy efficiency—an intelligent feature that is both eco-friendly and cost-effective!

It is worth noting that brake applications extend beyond forklifts. They are widely used in elevators, escalators, lifting equipment, wind power generation, and more. Electric transport vehicles represent just one of many applications. Specifically, the brakes used in such vehicles typically function as power-off brakes, meaning they engage automatically when the power is cut off, ensuring safety.

Key Selling Points of Forklift Brakes

01. Enhanced Safety & Reliability

Premium forklift brakes deliver consistent braking force under diverse operating conditions. They maintain optimal stopping performance whether handling heavy loads or navigating inclines, ensuring operator confidence during material handling operations. This reliability proves particularly crucial in warehouse environments with dense shelving layouts, where predictable braking prevents accidents and safeguards both personnel and infrastructure.

02. Superior Responsiveness

High-performance braking systems provide instantaneous engagement during emergency situations, significantly reducing stopping distances. This rapid response capability enables operators to avoid collisions effectively, making it especially valuable in high-throughput environments such as sorting facilities and production-adjacent warehouses where operational intensity demands precision control.

03. Extended Durability

Utilizing advanced wear-resistant materials, these brakes demonstrate exceptional longevity that reduces replacement frequency and lowers maintenance expenditures. The resulting reduction in downtime directly enhances operational efficiency while delivering measurable cost savings - a combination that resonates strongly with warehouse management professionals.

04. Simplified Maintenance

Engineered with serviceability in mind, these braking systems facilitate streamlined inspection and repair processes. Many contemporary designs incorporate smart diagnostic systems that provide early fault detection, enabling proactive maintenance planning and preventing unexpected operational disruptions through predictive maintenance alerts.

Key Considerations for Selection

When sourcing a replacement brake, accurately identifying the following core specifications is essential to ensure compatibility and proper function:

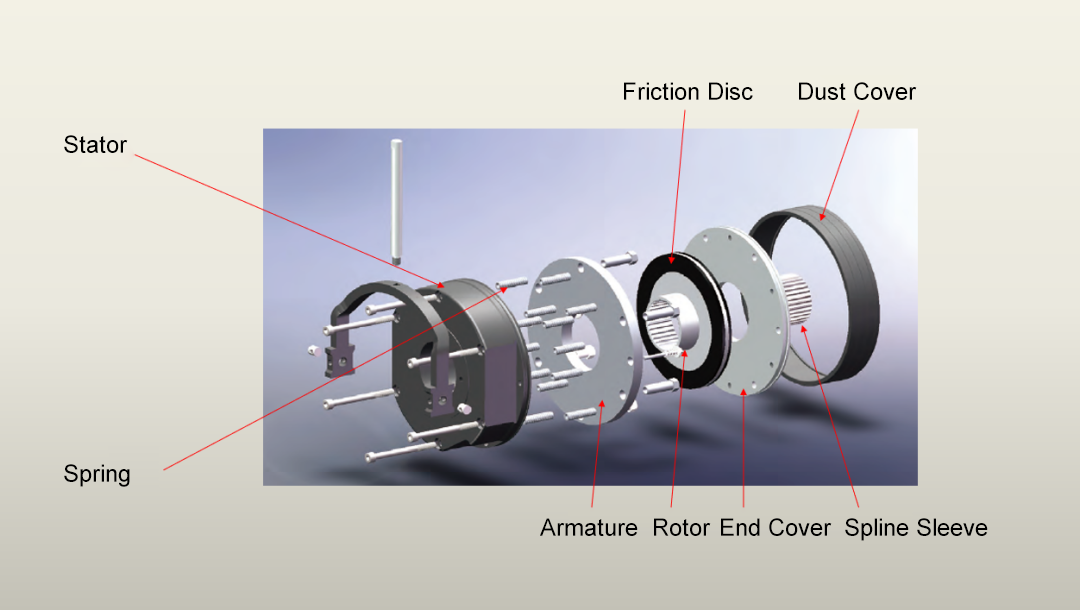

Motor Configuration: Determine whether the motor is horizontal or vertical, as the brake design must correspond to the motor's orientation.

Overall Diameter: Measure the brake's major outer diameter to confirm it fits within the allocated space.

Mounting Hole Centers: Ascertain the distance between the centers of the two mounting screws for a correct physical attachment.

Spline Specifications: Identify the major outer diameter and the profile of the spline teeth to guarantee a proper connection with the motor shaft.

Maintenance Precautions

01. Use Professional Tools

Always employ the correct tools when maintaining brakes. Using improper tools is like trying to tighten a screw with chopsticks—it may lead to messy results and component damage. Ensure you have suitable wrenches, screwdrivers, and other tools on hand, and always follow standard maintenance procedures.

02. Follow Operating Procedures

Strictly adhere to the maintenance manual provided by the manufacturer. Never arbitrarily modify the brake's structure or settings. Just as cooking requires following a recipe, unauthorized alterations may lead to failures. The manufacturer's manual offers the most suitable maintenance methods for your equipment, and compliance helps prevent unnecessary malfunctions and losses.

03. Prioritize Personal Safety

When inspecting or maintaining brakes, always wear appropriate personal protective equipment (PPE) such as gloves and safety goggles. Safety first—avoid injuries during maintenance. Use tools carefully, maintain a tidy work environment, and keep hands or body away from rotating components.

04. Prevent Environmental Pollution

Dispose of used brake fluid and worn components properly to avoid environmental contamination. Handle these wastes with the same care as sorted garbage—do not let them become an environmental hazard. Many localities have designated waste disposal sites where such materials can be safely processed.

05. Conduct Regular Training

Provide periodic training for operators and maintenance personnel to ensure they are updated on the latest maintenance techniques and safety protocols. Regular training not only enhances the team's skill level but also extends equipment service life and improves overall operational efficiency.

In summary, the forklift brake is a critical component for ensuring safe operation, with its performance directly impacting both efficiency and safety. Understanding the brake's functions, key features, maintenance procedures, and care precautions empowers operators and managers to better utilize and maintain this essential device. Through regular maintenance and scientific upkeep, we can significantly enhance the brake's reliability and service life, thereby guaranteeing smooth forklift operations.

We hope this article has provided you with a comprehensive understanding of forklift brakes and highlighted the importance of their maintenance for safer and more efficient work. Thank you for reading. We hope you found it helpful. Should you require any forklift parts, please do not hesitate to contact us!