The world's first forklift truck was born at Yale University in the United States in 1923. It was an electric model equipped with a vertical mast and lifting forks, utilizing a chain ratchet and pinion system for its lifting mechanism. Notably, its forks could be raised higher than the truck itself. This product was launched onto the global market and received widespread acceptance. It has now been exactly one hundred years since its introduction. However, providing a precise definition for a forklift remains surprisingly difficult, as there is still no universally accepted definition globally.

In China, forklifts are still categorized as a sub-sector of construction machinery, a classification largely stemming from historical reasons. While forklifts can be used in construction settings, such applications constitute a very small portion of their overall usage, making the "construction machinery" label somewhat inaccurate. Furthermore, the current international convention of classifying forklifts as industrial vehicles also suffers from historical limitations. Indeed, forklifts were born out of industrial needs, but their modern applications extend far beyond, permeating every sector of the national economy. They are now ubiquitous in any place requiring material handling, including hospitals, restaurants, and supermarkets.

Therefore, based on the above analysis, forklifts should not be narrowly classified as construction machinery, nor should they be referred to solely as industrial vehicles.

Definition of Forklift Truck

A forklift truck, also known as a fork-type loading and unloading vehicle, primarily uses forks as its load-handling device. It relies on a hydraulic lifting mechanism to raise and lower cargo and a wheeled travel system for horizontal transport. Beyond standard forks, it can be equipped with various attachments, allowing it to handle goods of diverse shapes and sizes, including containers. When fitted with buckets or boxes, it can also manage bulk materials. Operated by a driver, the forklift can independently perform tasks like picking up goods, unloading, stacking, destacking, and moving, eliminating the need for manual labor from stevedores. According to regulations set by the International Organization for Standardization (ISO/TC110), the forklift is classified as an industrial vehicle. It is widely used in various departments of the national economy, such as railway stations, ports, airports, factories, and warehouses, serving as highly efficient equipment for mechanized loading, unloading, stacking, and short-distance transportation.

Throughout history, humans have continuously sought more efficient and convenient ways to transport goods. From the "Wooden Ox and Gliding Horse"—an invention attributed to Zhuge Liang, the chancellor of the Shu Han dynasty during the Three Kingdoms period—to the modern era, numerous innovations have emerged. It was not until recent times that the industrial product we now know as the forklift truck began to take shape.

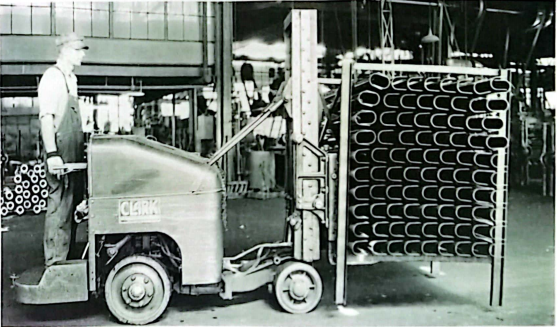

The question of when and by whom the world’s first forklift was manufactured may seem simple, yet it long perplexed the industry. In 1923, engineers at Yale University in the United States developed the first electric forklift truck equipped with a vertical mast and lifting forks. The following year, in 1924, Clark Company in the U.S. modified its original DUAT truck to create the world’s first internal combustion forklift.

World War II provided a significant impetus for the development of forklift production, particularly in the United States. A clear example of this was the U.S. Army’s use of forklifts to transport large quantities of military supplies on ships. There was a pressing need for entire fleets of forklifts capable of extremely rapid unloading, even aboard U.S. Navy vessels. With the rapid increase in forklift production, the era of relying heavily on manual labor for such tasks came to an end. It is estimated that Clark produced around 2,000 forklifts per month during this period—a stark contrast to the pre-war output of only 50 to 75 units per month.

During World War II, Clark supplied 90% of the forklifts used in the U.S. military economy. As American forces deployed around the globe, Clark forklifts also made their way worldwide. At one point, the name "CLARK" even became synonymous with forklift trucks.

Applications of Forklift Trucks

Forklift trucks, also known as fork-type cranes, are mechanical devices designed for material handling and stacking, with a wide range of applications. Our company specializes in forklift parts . Visit www.lifttops.com for more information.Below is an introduction to several key areas where forklifts are commonly used:

Warehousing and Logistics

Forklifts are extensively used in the warehousing and logistics industry. They are employed in loading and unloading goods, transportation, stacking, and storage. They can easily retrieve items from shelves or place them back, as well as move cargo onto transport vehicles for distribution.

Manufacturing

In the manufacturing sector, forklifts are primarily used for handling, moving, and stacking raw materials and finished products. They are capable of carrying heavy items and, due to their flexibility, can adapt to various working environments, enhancing both production efficiency and workplace safety.

Port Operations

Forklifts play a vital role in loading, unloading, and stacking goods in ports. Equipped with lifting devices and stackers, they facilitate the transfer of maritime cargo between ships and docks, ensuring swift and efficient turnover.

Construction and Building Materials

Forklifts are also widely used in the construction and building materials industry. They are ideal for moving heavy materials such as steel beams and concrete panels, as well as other supplies including bricks, stones, and equipment components.

Agriculture

In agriculture, forklifts are used across a broad spectrum of tasks—from handling bulk feed to moving hay bales. They support the storage and transportation of most agricultural products, streamlining storage processes and improving overall efficiency in agricultural production.

In summary, forklifts are essential equipment in industries such as manufacturing, goods transportation, and storage, significantly improving work efficiency and safety. Their flexibility, maneuverability, and adaptability make them well-suited for diverse working environments, and they can be customised to meet specific operational needs.

If you have any technical questions about forklifts or require forklift parts, please feel free to contact us!